MINISTRY OF EDUCATION AND SCIENCES OF THE REPUBLIC

KAZAKHSTAN

TARAZ STATE PEDAGOGICAL

UNIVERSITY

Faculty: Chemistry and Biology

Chair: Chemistry and MTH

CHEMICAL ANALYSIS OF MAYONNAISE

Completed: Sarsekeyeva I.S. group X-16-1

Leader: Kambarova E.A.

Taraz – 2017г.

ANNOTATION OF SCIENTIFIC WORK

Title: Chemical analysis of mayonnaise

1. GRNTI: 31.27.29

2. University: Taraz State Pedagogical University

3. Year of completion: 2017

4. Scope of work: 20

5. Number of applications:6

6. Number of illustrations:15

7. Number of tables: 4

8. Number of sources of literature: 23

Description of work:

1. Goal: To find the most accessible methods for determining the quality of mayonnaise and to verify the correctness of my hypothesis, as well as to conduct various analytical experiments.

2. Methods of research: Chemical method of investigation.

3. The main results of scientific research (scientific, practical): In this article, mayonnaise and various experiments

4. Availability of documents on the use of scientific results (yes, no): no

Sarsekeeva I. S.____________

CONTENT

Introduction ………………………………………………………….......4

Chapter 1. Study of the physical and chemical properties of mayonnaise

1.1. Literature review

1.1.1 History of mayonnaise............................................................................5

1.1.2. Composition of mayonnaise..................................................................6

Chapter 2. The Experimental Section

2.1.Methodics of the study

2.1.1. Identification features of the formulation composition of different types of mayonnaise.................................................................................................8

2.1.2. Determination of the mass fraction of water in mayonnaise...............10

2.1.3. Study of the process of demulsification of mayonnaise......................11

2.1.4. Determination of unsaturated fats in mayonnaise...............................11

2.1.5. Detection of starch in mayonnaise......................................................12

2.1.6. Determination of the acidity of mayonnaise………………………...12

2.1.7. Determination of protein in mayonnaise…………………………….12

2.2.Results of the study

2.2.1. Results of determining the quality of mayonnaise on the label..........13

2.2.2. The results of determining the mass fraction of water in mayonnaise………………………………………………………………………..13

2.2.3. Results on the process of demulsification of mayonnaise..............................................................................................................14

2.2.4. Results of determination of unsaturated fats in mayonnaise..............................................................................................................14

2.2.5. Results of detection of starch in mayonnaise....................................14

Conclusions……….....…………………………………………..…..…....15

Bibliographic reference…………………………………….………….....16

Appendix ……………………………………………….…………...........18

INTRODUCTION

Kazakhstanis are the most mayonnaise-loving people in Asia. The consumption of mayonnaise in the cities of the Republic of Kazakhstan is more than 58 thousand tons per year or 3.5 kg per capita per year[1]. Mayonnaise (/meɪəneɪz/ or in AmE also /mæneɪz/, and often abbreviated as mayo /meɪoʊ/) is a thick, creamy dressing often used as a condiment.[2] It is a stable emulsion of oil, egg yolk, and either vinegar or lemon juice,[3] with many options for embellishment with other herbs and spices. Proteins and lecithin in the egg yolk serve as emulsifiers in both mayonnaise and hollandaise sauce.[4] Commercial egg-free alternatives are available for vegans and others who want to avoid animal productsand cholesterol, or who are allergic to eggs[5]. Mayonnaise varies in color, but is often white, cream, or pale yellow. It may range in texture from that of light cream to a thick gel. In countries influenced by French culture, mustard is also a common ingredient, but the addition of mustard turns the sauce into a remoulade with a different flavor and the mustard acts as an additional emulsifier.[6]

The hypothesis of the study was the assumption that mayonnaise, which we use does not meet the quality specified by GOST and also provides very great harm to our body.

Mayonnaise can be approached not only from the consumer, but also from the research point of view, since recently we buy low-quality mayonnaise or even fake, so we decided to study the methods for determining the quality of mayonnaise and choose the most affordable.

The aim of the study was to find the most accessible methods for determining the quality of mayonnaise and to check whether our hypothesis is true

To achieve this goal, we have set ourselves the following tasks:

to study the literature on this problem;

to study the physico-chemical composition of mayonnaise;

to conduct various experiments;

analyze the results of the study and draw conclusions.

The subject of the study was mayonnaise of different types of company:

mayonnaise «3 желание»

mayonnaise «Солнечная линия»

mayonnaise «Saltanat»

The subject of the study was the physicochemical composition of mayonnaise.

Research methods: observation, analysis of literature, chemical experiment.

The chemical laboratory of the Taraz State Pedagogical University became the base of the research.

The practical significance of the work is that the knowledge gained will teach us to determine the quality of mayonnaise by the most accessible methods. And this in turn will help to take care of your health.

The structure of the work consists of an introduction, two chapters, conclusions, results, conclusion, a bibliography, an appendix.

CHAPTER 1. STUDY OF PHYSICAL AND CHEMICAL PROPERTIES OF MAYONNAISE

1.1. Literature review

1.1.1. History of mayonnaise

The word mayonnaise was not used for a dressing before the start of the 19th century. The earliest reference appears to be by Alexandre Viard (1806), who however never quite gives a recipe for the dressing itself.[7] At that point, the sauce was made with aspic or jelly, rather than an egg emulsion. In 1815, Louis Eustache Ude wrote:

No58.—Mayonnaise.

Take three spoonfuls of Allemande, six ditto of aspic, and two of oil. Add a little tarragon vinegar, that has not boiled, some pepper and salt, and minced ravigotte, or merely some parsley. Then put in the members of fowl, or fillets of soles, &c. Your mayonnaise must be put to ice; neither are you to put the members into your sauce till it begins to freeze. Next dish your meat or fish, mask with the sauce before it be quite frozen, and garnish your dish with whatever you think proper, as beet root, jelly, nasturtiums, &c.[8]

In a 1820 work, Viard describes something like the more familiar emulsified version:

This sauce is made to "take" in many ways: with raw egg yolks, with gelatine, with veal or veal brain glaze. The most common method is to take a raw egg yolk in a small terrine, with a little salt and lemon juice: take a wooden spoon, turn it while letting a trickle of oil fall and stirring constantly; as your sauce thickens, add a little vinegar; put in too a pound of good oil: serve your sauce with good salt: serve it white or green, adding green of ravigote or green of spinach.

This sauce is used for cold fish entrees, or salad of vegetables cooked in salt water.[9]

In 1808, Grimod de La Reynière referred to a "bayonnaise" sauce: "But if one wants to make from this cold chicken, a dish of distinction, one composes a bayonnaise, whose green jelly, of a good consistency, forms the most worthy ornament of poultry and fish salads."[10]

One of the most common places named as the origin of mayonnaise is the town of Mahón in Menorca, Spain, where it was then taken to France after Armand de Vignerot du Plessis's victory over the British at the city's port in 1756. According to this version, the sauce was originally known as salsa mahonesa in Spanish, still an accepted form together with "mayonesa",[11] and maonesa (later maionesa) in Catalan (as it is still known in Menorca), with French mayonnaise being incorporated into English following popularization in French cuisine.[12]

The Larousse Gastronomique suggests: "Mayonnaise, in our view, is a popular corruption of moyeunaise, derived from the very old French word moyeu, which means yolk of egg."[13] The sauce may have been named mayennaise after Charles de Lorraine, duke of Mayenne, because he took the time to finish his meal of chicken with cold sauce before being defeated in the Battle of Arques.[14]

According to Trutter et al.: "It is highly probable that wherever olive oil existed, a simple preparation of oil and egg came about — particularly in the Mediterranean region, where aioli (oil and garlic) is made."[12]

The Oxford English Dictionary records the use of the word "mayonnaise" in English in 1815.[15]

1.1.2 Composition of mayonnaise

Mayonnaise is a multi-component product based on liquid vegetable oils and flavorings. In addition to vegetable oil and water, it includes egg powder, sugar, mustard, vinegar or lemon juice, milk powder, salt, spices. It has much of what our body needs - fats, proteins, carbohydrates, minerals.

In any developed country, sauce, in which oil is less than 80%, will not be considered mayonnaise - it will be salad dressing, or salad dressing - if the oil is less than 60%[16].

Chemistry is an amazing science, and various flavors, dyes, emulsifiers, flavors give the mixture not only the desired taste, but also the smell, and color, and consistency.

Mayonnaise is a product obtained from cheap vegetable oils and then formed as a creamy, fine oil-in-water emulsion from refined deodorized vegetable oils, water, milk, salt, sugar, food acid, emulsifiers, antioxidants, preservatives, food colors and other components.

Many products, including mayonnaise, are often supplemented with substances that can affect our neurons - they cause a real food addiction.

What is the difference between a real mayonnaise and what is offered in stores? Of course, not only the amount of oil, but also other characteristics: the composition, the quality of the ingredients and the way they are combined.

The color of this mayonnaise resembles the color of honey - it is translucent; the consistency is tender, reminiscent of jelly, and the taste is very delicate.

Store this mayonnaise for a long time does not work: at most - a week in the refrigerator.

The original recipe for mayonnaise is not suitable for long-term storage, in connection with which industrial mayonnaise was developed for industrial production. Mayonnaise produced in an industrial manner is by no means the most health-friendly product and its use in the daily diet is not recommended. [17]

At us all mayonnaises, made by the food industry, are surrogate: the oil in them is partially replaced with milk or water, and fresh egg yolks - with egg powder.

Obtain an emulsion of powder and oil is not obtained, and oil and water - especially when it comes to normal cooking conditions. But then stabilizers and emulsifiers come on the scene - very persistent synthetic substances, besides the whole mass is beaten up by powerful machines, so that even in water the emulsion of the oil turns out to be stable, and the shelf life is very long.

When making mayonnaise, as a rule, it is used:

1. Refined (refined) and deodorized (odorless) sunflower oil and only in small amounts of soybean and cottonseed. Since the oil is in a dispersed state (that is, in the form of small fat globules scattered in the water column), it is perfectly digested. And, therefore, irreplaceable (polyunsaturated) fatty acids contained in it, which are known to be responsible for maintaining immunity, elasticity of blood vessels, do not vanish[18].

If you mix the vegetable oil with water and leave it alone for a while, the small fat balls will gather in larger ones and the emulsion will begin to separate. To prevent this from happening, stabilizing substances are added to it, which, penetrating the shell of fat droplets, prevent their fusion.

2.Stabilizers. In domestic mayonnaise, the role of stabilizers is performed by skimmed milk powder, egg and mustard powders. Dry milk not only helps to form a structure, but also is a source of protein[19].

• Egg powder - a mixture of egg yolk and egg whites - promotes the formation of a strong emulsion, affects the color (mayonnaise usually does not add colorants) and consistency[20].

• Mustard powder and vinegar give the sauce a sharp taste and aroma.

• Acetic acid suppresses the development of bacteria. Those who do not like vinegar, can choose mayonnaise, containing wine vinegar or vinegar infusions on herbs and roots. Vinegar should be clear without sediment. Weak coloration is allowed. The taste should be sour, strong and pure, characteristic for vinegar. Tartness is not allowed. Mayonnaise and other acetic acids are allowed to be used in the production of mayonnaise, authorized by the state sanitary and epidemiological supervision for the manufacture of food products.

• Spices are red ground pepper, ginger, cloves, bay leaves, caraway seeds and some herbs.

• salt, sugar, food extracts, spices.

• In addition to vegetable oil and water, mayonnaise includes food additives that give different taste and aroma to mayonnaise, allowing to create a large assortment of these products.

Mayonnaise includes:

• substances that improve the appearance (dyes);

• substances regulating the consistency (thickeners, emulsifiers, stabilizers), substances that regulate taste and aroma (flavors, flavors);

• Substances that increase safety and increase shelf life (preservatives, antioxidants).

In high-calorie mayonnaises, stabilizers and thickeners are kept in the least amount, but when added to medium- and low-calorie mayonnaise, their dose is increased. Most often, modified starches are used, which do not bring any benefit to the human body. To be afraid of them, too, should not be, since they are introduced into the formulation in an amount that is safe for human health. Often on labels in the composition of mayonnaise, you can read such names as guar gum (E412) and hamulsion. These components are also introduced into the product to maintain the desired consistency. Preservatives (potassium sorbate E202, sodium benzonate E211, etc.) prevent fast spoilage of mayonnaise, suppressing the development of yeast and mold fungi[21].

The more water in this mayonnaise, the more cloudy and white it will turn out.

Although it turns out that the producers mix the oil with water, it is impossible to achieve the necessary density without additives, and so in mayonnaise add something that would not have dreamed of a French chef and a nightmare - a brewed mixture of wheat flour and starch.

Yolks or egg powder deteriorate very quickly when combined with water, therefore, preservatives should be put more.

Light and low-caloric name the product, in which there is very little oil, but a lot of flour, water, and any additives.

"Olive" mayonnaise is a product with the addition of olive oil, which there is no more than 5-10% - and this at best[22].

CHAPTER 2. EXPERIMENTAL PART

2.1.Methodics of the study

2.1.1. Study of the composition of mayonnaise on packaging.

Identification of mayonnaise.

Mayonnaise is a product obtained from cheap vegetable oils and then formed as a creamy, fine oil-in-water emulsion from refined deodorized vegetable oils, water, milk, salt, sugar, food acid, emulsifiers, antioxidants, preservatives, food colors and other components.

All mayonnaises are divided into the following types: high-fat, medium-fat and low-fat[23]. According to the current standard for mayonnaise for the first time in Kazahstan introduced falsified information for the consumer types: high-calorie, medium-calorie, low-calorie. Caloric content of mayonnaise can be formed both due to fats, and due to carbohydrates or proteins. Therefore, the classification of mayonnaise by caloric content leads only to the consumer's misconception about the true composition of the product[23].

Table 1. Identification features of individual types of mayonnaise

| Indicator name | Characteristic of the indicator for | ||

| high-fat | medium-fat | low-fat | |

| Fat content, in% | more than 55 | 40-55 | less than 40 |

| Water content, in% | less than 35 | 35-50 | more than 50 |

Table 2.Identification features of the formulation composition of different types of mayonnaise.

| Name of components | Content of components in mayonnaise, in% | ||

| Saltanat | Солнечная линия | 3 желания | |

| Vegetable oil | 67 | 46 | 36 |

| Water | 24,15 – 23,65 | 43,45 | 51,91 |

| Egg powder | 5,0 | – | – |

| Milk, dry, low-fat | 1,6 | 1,6 | 3,0 |

| Dry soy milk | – | – | 4,0 |

| Soy flour | – | – | 1,0 |

| FOLS Emulsifier | – | 0,6 | – |

| Whey Protein Concentrate | – | 2,5 | – |

| Phospholipid dietary supplements | – | – | 0,18 |

| Corn starch phosphate grade B | – | 2,0 | – |

| Sodium alginate | – | – | 0,40 |

| Mustard powder | 0,75 | 0,25 | 0,6 |

| Baking soda | 0,05 | 0,05 | 0,06 |

| Sugar - sand | 1,5 | 1,5 | 1,0 |

| Cooking salt | 1,0 – 1,3 | 1,1 | 1,2 |

| Acetic acid is 80% | 0,55 – 0,75 | 0,65 | 0,65 |

Table 3. Chemical composition of the product "mayonnaise"

| № № | Nutritional in substances, vitamins, microelements | Compound in 100 gr. product | № | Nutritional in substances, vitamins, microelements | Compound in 100 gr. product |

| 11. | Water | 25.0 gr | 11. | Vitamin E | 32.0 mg |

| 22. | Proteins | 3.1 gr | 12. | Vitamin PP | 0.03 mg |

| 33. | Fats | 67,0 gr | 13. | Choline | 14,03 mg |

| 44. | Carbohydrates | 2,6 gr | 14. | Iron | 1,0 mg |

| 55. | Organic acids | 0,6 gr | 15. | Potassium | 48,0 mg |

| 66. | Ash | 1,4 gr | 16. | Calcium | 28,0 mg |

| 77. | Vitamin A | 0,02 gr | 17. | Magnesium | 11,0 mg |

| 88. | Vitamin B1 | 0,010 mg | 18. | Sodium | 508,0 mg |

| 99. | Vitamin В2 | 0,05 mg | 19. | Phosphorus | 50,0 mg |

| 110. | Vitamin В6 | 0,010 mg | | | |

2.1.2. Determination of the mass fraction of water in mayonnaise.

Equipment: Bucks, glass stick, analytical balance, drying cabinet, mayonnaise.

Work progress: A thoroughly washed bottle with a glass rod was dried for 30 minutes in an oven at 120 ° C, cooled in a desiccator and weighed on an analytical balance m0

Weighed a can of mayonnaise in a weighed bag, closed the lid with a lid and weighed it on an analytical balance: m1

Buks with a glass rod and a portion of mayonnaise and a lid placed on the rib were placed in a drying cabinet preheated to 150 ° C. After 40 minutes, the bag was closed with a lid and transferred to a desiccator for cooling. After cooling after 15-20 minutes, the bag was weighed on an analytical scale: m2

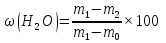

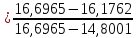

Further, the moisture content of mayonnaise was determined by the formula:

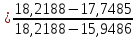

2.1.3. Study of the process of demulsification of mayonnaise.

Demulsification is the process of destruction of a stable emulsion, which reduces to coalescence, that is, stratifying it into free liquid phases: chemical and thermal.

Chemical destruction.

Equipment: A tripod with test tubes, glass sticks, concentrated sulfuric acid, mayonnaise.

Progress: The tubes were numbered.

Tube №1 – «Saltanat»

Tube №2 – «Солнечная линия»

Tube №3 – «3 желания»

10 g of mayonnaise were added to each tube and 2-3 ml of concentrated sulfuric acid were added.

2.1.4. Determination of unsaturated fats in mayonnaise.

Chemicals and equipment: A tripod with test tubes, glass sticks, a solution of potassium permanganate (manganese)

Progress: The tubes were numbered.

Tube №1 – «Saltanat»

Tube №2 – «Солнечная линия»

Tube №3 – «3 желания»

10 g of mayonnaise were added to each tube and 2-3 ml of potassium permanganate were added.

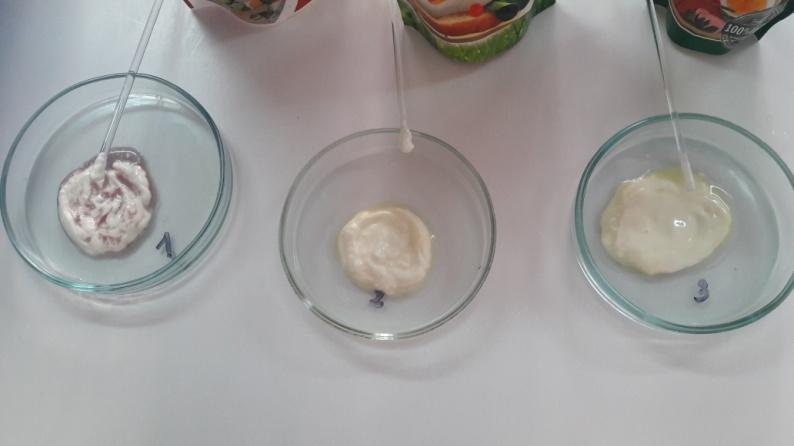

2.1.5. Detection of starch in mayonnaise.

Chemicals and equipment: Petri bowls, glass sticks, tincture of iodine, mayonnaise

Progress: The tubes were numbered.

Bowl №1 – «Saltanat»

Bowl №2 – «Солнечная линия»

Bowl №3 – «3 желания»

In each cup 10 g of mayonnaise were added and 2-3 drops of iodine

2.1.6 Determination of the acidity of mayonnaise

Materials and equipment: burette, pipettes for 10 and 20 ml, a conical flask for 100 ml.

Reagents:

Decinormal (0.1 N) alkali solution (NaOH or KOH).

1% solution of phenolphthalein.

Explanation of the assignment:

By the acidity of mayonnaise, one can judge its freshness and naturalness. New milk

has bactericidal properties, has an amphoteric response to litmus (red

litmus paper turns blue, and blue blushes)

After a while, microorganisms begin to develop into mayonnaise, first of all

Lactic acid bacteria that ferment milk sugar and form a dairy

acid, which increases the acidity of mayonnaise. In addition, the acidity of mayonnaise with acid

character of proteins.

The acidity of mayonnaise is higher the longer it is stored uncooled. Titrated

the acidity of mayonnaise is determined in conditional degrees T 0 (Turner). By conditional degree

T

◦

mean the number of milliliters of a decinormal solution (0.1N) of alkali (NaOH or

KOH), necessary to neutralize 100ml of mayonnaise. Indicator is 1 percent

solution of phenolphthalein.

1. Titration with alkali.

To 50 ml of milk add 4 ml. solution of phenolphthalein and titrate the resulting mixture

solution of alkali until the appearance of pink color. The doubled volume of the added reagent

(in ml.) is numerically equal to the number of degrees of acidity of milk.

Fresh mayonnaise should have 16-18 and not more than 21 degrees of acidity.

2.1 6 Determination of protein in mayonnaise.

Materials and equipment: a 100-200 ml flask, a 100-ml beaker, a burette,

pipette for 10ml, glass rod.

Reagents:

Decinormal alkali solution (NaOH).

1% alcohol solution of phenolphthalein.

Neutral 37-40 percent solution of formalin. To a 37-40% solution

formalin (100 ml) add 3-4 drops of a 1% alcohol solution of phenolphthalein

and with constant agitation, 0.1 N alkali solution is poured from the burette before the appearance

pale pink staining.

2.2.Results of the study

2.2.1.The result of determining the quality of mayonnaise for packaging. (Appendix No. 1)

As a result of determining the quality of mayonnaise for packaging, found that:

1. Sunflower refined deodorized oil is contained in all kinds of mayonnaise.

2. Water is contained in all types of mayonnaise.

3. Egg yolk is found in all types of mayonnaise.

4. Sugar is found in all types of mayonnaise.

5. Salt is found in all types of mayonnaise.

6. The vinegar of food raw materials is contained in all types of mayonnaise.

7. Mustard oil is contained in all types of mayonnaise.

8. Preservative sorbic acid is found in all types of mayonnaise.

9. The dye β-carotene is not contained in mayonnaise "3 desires"

10. Starch corn is not contained in mayonnaises "Solar line" and "3 desires"

11. Olive oil is not refined in mayonnaise

12. Black pepper extract is not contained in mayonnaise.

13. Saccharin is not contained in mayonnaise.

2.2.2. Results of determining the mass fraction of water in mayonnaise.

As a result of the determination of the mass fraction of water in mayonnaise, it was found that: (Appendix No. 2)

1. In the mayonnaise «Saltanat» the largest mass fraction of water.

m0 = 14,8001

m1=16,6965

m2 =16,1762

W(H2O)

W (H2O) =27,44%

And in Mayonnaise «Солнечная линия» the smallest mass fraction of water.

m0 = 15,9486

m1 = 18,2188

m2 = 17,7485

W(H2O)

W (H2O) =20,71%

2.2.3. Results of studying the process of demulsification of mayonnaise

Chemical destruction.

As a result of chemical destruction with mixing, a stratification of mayonnaise into 2 phases was observed in all test tubes.

Thermal failure.

As a result of thermal destruction, a stratification of mayonnaise into two liquid phases was observed. When heated, adsorption of the emulsifier decreases and the number of collisions of emulsion droplets increases, which leads to their merging and coalescence.

2.2.4. Results on the determination of unsaturated fats in mayonnaise.

As a result of the determination of unsaturated fats in mayonnaise, discoloration was observed in all chemical beakers. Thus, the composition of mayonnaise includes unsaturated fats.

2.2.5. Results of detection of starch in mayonnaise.

As a result of the detection of starch in mayonnaise, the staining in blue in the cup under No. 1 was observed after a while with stirring. This means that starch in this mayonnaise is present.

Conclusions

1. Conclusions on the study of the composition of mayonnaise on packaging.

The consumer can check the quality of mayonnaise without resorting to experiments and expertise. Without departing from the counter, you will get acquainted with the composition of mayonnaise on the package. But the consumer can not know the percentage of the components.

2. Conclusions of the determination of the mass fraction of water in mayonnaise

Thus, the smallest mass fraction of water in Mayonnaise «Солнечная линия»

And the highest mass fraction of water in mayonnaise «Saltanat»

3. Conclusions on the process of the demulsification of mayonnaise.

Chemical destruction.

After some time, the stratification of mayonnaise into 2 phases was observed with stirring. This means that manufacturers have added thickeners to the norm.

4.Conclusions determination of the acidity of mayonnaise and determination of protein in mayonnaise.

To express the acidity of the investigated mayonnaise in the conventional degrees of Turner (T0)

the amount of millimeters of alkali consumed for titrating 10ml of milk is multiplied

by 10, i.e. made recalculation for 100ml mayonnaise. The titration was 1.8 ml 0.1N

solution of alkali. Titrated acidity is:

1.8 * 10 = 180

T. Hence - the mayonnaise is fresh.

To titrate 10 ml of milk (after adding 2 ml of neutral formalin)

1.7 ml of 0.1 N alkali was consumed; the protein content will be: 1.7.

1.94 = 3.298%

(after rounding - 3.3%).

4. Determination of unsaturated fats in mayonnaise.

Thus, the composition of mayonnaise includes unsaturated (vegetable) fats. Tubes 1, 2, 3, discolored because the composition of mayonnaises include unsaturated (vegetable) fats. And in the case of non-discolouration, virtually harmless vegetable oil is excluded from the formulation, and it is replaced with water and genetically modified starch, gelatin, emulsifiers and thickeners. The harm of mayonnaise in this case is obvious.

5. Detection of starch in mayonnaise.

After some time, with stirring, the coloring in blue at No. 1

But it should be noted that the producers indicated in the starch composition (see Appendix No. 1) So, this time the manufacturer did not deceive consumers.

CONCLUSION

What is mayonnaise - everyone knows. Rather, most people think that they know this, but in fact have not tried and seen this famous sauce.

What is sold in our stores under this name is simply an industrially prepared chattle, the taste and even the kind of which has nothing to do with real mayonnaise.

Many products, including mayonnaise, often add substances that can affect our neurons - they cause a real food addiction.

Mayonnaise, bought in the store, literally interrupts the taste of any dish - wherever it is put? The present sauce always emphasizes and shades the taste of the dishes, and does not drown it.

Forever stop eating the industrial surrogates, which have nothing to do with the world-famous sauce, except for the name written on their packages. Prepare mayonnaise for yourself - it only takes 8-10 minutes. And the present mayonnaise - such as it is supposed to be in the diet of decent people - is enough for a whole week. With longer storage in the refrigerator, this mayonnaise does not become toxic, but gradually loses that delicious taste, which made him the king of all sauces.

BIBLIOGRAPHIC DIRECTORY

Was taken from the site www.isas.kz "King of sauces". Short review for 2015.

"Mayo - Definition and More from the Free Merriam-Webster Dictionary". Merriam-webster.com. Retrieved 14 February 2015.

"Mayonnaise is an emulsion of oil droplets suspended in a base composed of egg yolk, lemon juice or vinegar, which provides both flavor and stabilizing particles and carbohydrates." On Food and Cooking, Harold McGee, Scribner, New York, 2004, p. 633.

"Science of Eggs: Egg Science". Exploratorium.edu. Retrieved 17 November 2011.

http://nypost.com/2011/09/17/hellmanns-mayonnaise-americas-best-selling-condiment

"Making an Emulsion". Science Project Ideas. 1 October 2010. Retrieved 17 November 2011.

"Le cuisinier impérial, n". Le cuisinier impérial. Barba (1806). Retrieved 24 November 2014.

"The French Cook, Or, The Art of Cookery: Developed in All Its Branches - Louis Eustache Ude - Google Books". Books.google.com. Retrieved May 30, 2015.

"Le cuisinier royal, n". Le cuisinier royal. Barba (1820). Retrieved 24 November 2014.

de La Reynière, Grimod (1808). Manuel des amphitryons. Capelle et Renand. Retrieved 26 November 2014.

"mayonesa". Diccionario panhispánico de dudas (in Spanish). Real Academia Española. October 2005. Retrieved 28 August 2017.

b Trutter, Marion; Beer, Günter (2008). Culinaria Spain (Special ed.). Germany: H.F. Ullmann. p. 68. ISBN 9783833147296.

Dictionnaire de l'Académie française, neuvième édition, "3. Anciennt. Le jaune de l'œuf."

Acton, Johnny; Adams, Tania; Packer, Matt (2006). The Origin of Everyday Things. New York: Sterling. p. 151. ISBN 978-1-4027-4302-3.

"mayonnaise". Oxford English Dictionary (3rd ed.). Oxford University Press. September 2005. (Subscription or UK public library membership required.)

Potter, Norman N.; Hotchkiss, Joseph H. (1998-01-01). Food Science. Springer Science & Business Media. ISBN 9780834212657.

Cobb, Cathy; Fetterolf, Monty L.; Goldsmith, Jack G. (2007-01-01). Crime Scene Chemistry for the Armchair Sleuth. Prometheus Books. ISBN 9781591025054.

Depree, J.A. & Savage, G.P. 2001. Physical and flavour stability of mayonnaise. Trends in Food Science and Technology 12: 157-163

Alan Imeson (2011), Food Stabilisers, Thickeners and Gelling Agents, John Wiley & Sons, ISBN 978-1-4443-6033-2

Griminger, P; Fisher, H (1986). "The effect of dried and fresh eggs on plasma cholesterol and atherosclerosis in chickens". Poultry science. 65 (5): 979–82.

Menezes, E.W., de Melo, A.T., Lima, G.H. & Lajolo, F.M. 2004. Measurement of carbohydrate components and their impact on energy value of foods. Journal of Food Composition and Analysis 17: 331-338.

Roche, H.M., Zampelas, A., Knapper, J.M., Webb, D., Brooks, C., Jackson, K.G., Wright, J.W., Gould, B.J., Kafatos, A., Gibney, M.J. & Williams, C.M. 1998. Effect of long-term olive oil dietary intervention on postprandial triacylglycerol and factor VII metabolism. The American Journal of Clinical Nutrition 68: 552-560.

Rajaram, S., Burke, K., Connell, B., Myint, T. & Sabate, J. 2001. A monounsaturated fatty-acid pecan-enriched diet favourably alters the serum lipid profile of healthy men and women. Journal of Nutrition 131: 2275-2279.

ATTACHMENT

Appendix №1. Identification features of the formulation composition of different types of mayonnaise.

Raw materials of mayonnaise production. Mayonnaise is a multicomponent system, and the qualitative and quantitative composition of the ingredients determines its functions and properties. In addition to vegetable oil and water, mayonnaise includes emulsifiers, stabilizers, structurants, as well as flavor, functional and other nutritional supplements that give different taste, aroma, nutritional and physiological value to mayonnaise and allow creating a large assortment of these products.

Fatty basis[18]. As a fat base for mayonnaise products, vegetable oils are used. These include sunflower, soybean, corn, peanut, cotton, olive. All vegetable oils for mayonnaise production must be refined and deodorized. The choice of the type of vegetable oil depends on the manufacturer, its capabilities. The collection of recipes to the standard technological regulations for the production of mayonnaise does not specify the type of vegetable oil, but requires its complete refining.

Emulsifiers[19]. In the production of mayonnaise, various combinations of emulsifiers are most often used, allowing them at low consumption to receive highly stable emulsions. In the production of mayonnaises, natural food surfactants (surfactants) are used as emulsifiers. As a rule, natural surfactants are protein-lipid complexes with different compositions of both high- and low-molecular emulsifying substances. Various combinations of natural emulsifiers can increase the emulsifying effect and reduce their overall consumption.

In our republic, the following types of egg products are used as the main emulsifying ingredients: egg powder, egg granulated product, egg yolk dry. The content of egg products in mayonnaise varies from 2 to 6%, depending on the formulation.

Stabilizers. A very important problem in the production of mayonnaise is the stabilization of the emulsion. For the stability of high-calorie mayonnaise, in some cases, only an emulsifier is sufficient. And to give less stable medium- and low-calorie mayonnaise emulsions long-term stability and protect them from stratification (with long storage, with changing temperature conditions, during transportation), stabilizers are added to the formulations. They should increase the viscosity of the dispersion medium, preventing the aggregation and coalescence of oil droplets, ie, they must be hydrophilic in nature.

Stabilizers that meet the requirements that mayonnaise manufacturers make to them should:

• be compatible with other food ingredients included in the product;

• provide the required consistency, which lasts for a long time even when cooked, and other consumer and technological properties of the product;

• have a low concentration and a regulated rate of education;

• be non-toxic and non-allergenic;

• have a low cost and a significant raw material base.

Thickeners. In the formulations of low-calorie mayonnaise (and sometimes also medium-caloric, containing a large mass fraction of water), stabilizers-structurizers are used to increase the stability of the emulsion. In general, these are starches and their derivatives, which are obtained from various industrial raw materials: maize, potato, wheat, rice, tapioca. In the production of mayonnaise, both native (requiring preparation) and modified (water-soluble) starches are used.

Native starches are well dispersed in water, but do not dissolve. When heated to a temperature of 55-85 ° C, they swell, forming a paste - starch paste. Therefore, in mayonnaise emulsions, as structure-forming agents, such starches are used after heat treatment. Formed from native starches of gluten are not sufficiently stable, prone to syneresis, subject to the influence of varying pH and temperature. To reduce adverse effects, starches are often mixed with stabilizers, which protect them from external factors, for example, high temperature or low pH.

Appendix №2. Results for determining the mass fraction of water in mayonnaise.

Table 4.Results for determining the mass

|

| m0 (gr) | m1(gr) | m2(gr) | ɷ(H2O)(%) |

| «Saltanat» | 14.8001 | 16.6965 | 16.1762 | 27.44 |

| «Солнечная линия» | 15.9486 | 18.2188 | 17.7485 | 20.71 |

| «3 желания» | 14.9549 | 17.1291 | 16.6051 | 24.10 |

Appendix №3. Results on the study of the process of demulsification of mayonnaise (chemical destruction)

Appendix №5. Results on the determination of unsaturated fats in mayonnaise.

2-3 ml potassium permanganate were added

discoloration in all beakers

Appendix №6. Detection of starch in mayonnaise.

10 g of mayonnaise was added to each dish

observed staining in blue in a cup under number 1

24

Получите свидетельство

Получите свидетельство Вход

Вход

Chemical analysis of mayonnaise (1.39 MB)

Chemical analysis of mayonnaise (1.39 MB)

0

0 821

821 2

2 Нравится

0

Нравится

0