Упражнения для студентов, обучающихся по профессии «Слесарь по контрольно-измерительным приборам и автоматике»

Automation

Automation is the system of manufacture performing certain tasks, previously done by people, by machines only.

The sequences of operations are controlled automatically.

The most familiar example of a highly automated system is an assembly plant for automobiles or other complex products.

The term automation is also used to describe nonmanufacturing systems in which automatic devices can operate independently of human control.

Such devices as automatic pilots, automatic telephone equipment and automated control systems are used to perform various operations much faster and better than could be done by people.

Automated manufacturing had several steps in its development.

Mechanization was the first step necessary in the development of automation.

The simplification of work made it possible to design and build machines that resembled the motions of the workers.

These specialized machines were motorized and they had better production efficiency.

Industrial robots, originally designed only to perform simple tasks in environment dangerous to human workers, are now widely used to transfer, manipulate, and position both light and heavy work pieces performing all the functions of a transfer machine.

| Automation | автоматизация |

| automatically | автоматически |

| automated system | автоматизированная система |

| manufacture | производство, производить |

| automated manufacturing | автоматизированное производство |

| nonmanufacturing system | непроизводственная система |

| task | задача, задание, урок |

| sequence | последовательность, очередность, порядок |

| familiar example | типичный пример |

| assembly plant | сборочный завод |

| term | термин |

| automatic devices | автоматические устройства |

| operate | выполнять работу, приводить в действие |

| operation | действие, управление, процесс |

| to perform | выполнять, производить |

| performing | выполнение |

| simplification | упрощение |

| to design | конструировать, разрабатывать |

| efficiency | продуктивность. производительность |

| environment | окружающая среда, внешние условия |

| to transfer | переносить, перемещать |

| to manipulate | манипулировать, управлять |

| to position | устанавливать, располагать |

| work pieces | детали, заготовки |

| transfer machine | станок-автомат, поточная линия |

Упражнение 1

Изучите данные слова, выполните следующие задания:

Выберите однокоренные слова.

Выберите глаголы.

Упражнение 2

Составьте словосочетания

| certain | of operations |

| the sequences | devices |

| automated | steps |

| automatic | machines |

| telephone | tasks |

| several | robots |

| specialized | example |

| Industrial | operations |

| work | equipment |

| various | pieces |

| familiar | system |

Упражнение 3

Образуйте существительные при помощи суффикса – tion и переведите их;

| to manipulate |

|

| to operate |

|

| to automate |

|

| to regulate |

|

| to demonstrate |

|

| to produce |

|

| to inform |

|

| to instruct |

|

Упражнение 4 Ответьте на вопросы:

How is the term automation defined in the text?

What is the most familiar example of automation given in the text?

What was the first step in the development of automation?

What were the first robots originally designed for?

Упражнение 5

Расширьте следующие предложения,

употребляя новые слова и словосочетания

The example of an automated system is an assembly plant.

Automatic pilots are used to perform various operations.

Automation is the system performing certain tasks.

Industrial robots are now widely used to transfer, manipulate, and position both light and heavy work pieces.

These machines were motorized

Упражнение 6 Составьте предложения, используя таблицу

| Mechanization | of a highly automated system | to transfer, manipulate, and position both light and heavy work pieces performing all the functions of a transfer machine. |

| Industrial robots | are used to perform | in the development of automation. |

| The most familiar example | are controlled | in its development. |

| Such devices as automatic pilots, automatic telephone equipment and automated control systems | was the first step | is an assembly plant for automobiles or other complex products. |

| Automated manufacturing

| had several steps | various operations much faster and better than could be done by people. |

| The sequences of operations | are now widely used | automatically. |

Тест

Инструкция: Вставьте пропущенные слова, пользуясь таблицей, сделайте перевод

Automation is the system of manufacture … certain tasks, previously done by… , by machines only.

The most … example of a highly … system is an assembly plant for … or other complex products.

The term … is also used to describe nonmanufacturing systems in which automatic … can operate … of human control.

Automated manufacturing had … steps in its development.

… was the first step necessary in the … of automation.

The simplification of work made it possible … and build machines that resembled the motions of the….

Industrial …, originally designed only to perform … tasks in environment … to human workers, are now widely used …, manipulate, and position both light and heavy … performing all the functions of a ….

Слова для справок:

| Familiar | automation | workers | work pieces | transfer machine |

| simple | performing | development | to transfer | automobiles |

| robots | to design | mechanization | independently | dangerous |

| several | devices | automated | people |

|

Types of automation

1. Manufacturing is one of the most important application areas for automation technology. 2. There are several types of automation in manufacturing.

3. The examples of automated systems used in manufacturing are described below.

4. Fixed automation, sometimes called “hard automation” refers to automated machines in which the equipment configuration allows fixed sequence of processing operations. 5. These machines are programmed by their design to make only certain processing operations. 6. They are not easily changed over from one product style to another. 7. This form of automation needs high initial investments and high productions rates. 8.That is why it is suitable for products that are made in large volumes.9. Examples of fixed automation are machining transfer lines in the automobile industry, automatic assembly machines and certain chemical processes.

10. Programmable automation is a form of automation for producing products in large quantities, ranging from several dozen to several thousand units a time.

11. For each new product the production equipment must be reprogrammed and changed over. 12. This reprogramming and changeover take a period of non-productive time. 13. Production rates in programmable automation are generally lower than in fixed automation.14. A numerical-control machine-tool is a good example of programmable automation. 15. The program is coded in computer memory for each different product style and the machine-tool is controlled by the computer program.

16. Flexible automation is a kind of programmable automation.17. Programmable automation requires time to reprogram and change over the production equipment for each series of new product. 18. This is lost production time, which is expensive.19. In flexible automation the number of products is limited so that the changeover of the equipment can be done very quickly and automatically.20. The reprogramming of the equipment in flexible automation is done at a computer terminal without using the production equipment itself. 21. Flexible automation allows a mixture of different products to be produced one right after another

Упражнение 7 Составьте предложения

| Manufacturing is | are | by their design to make | in the automobile industry |

| Fixed automation | requires time | application areas | reprogrammed and changed over |

| These machines | machine-tool | machining transfer lines | without using the production equipment |

| Examples of fixed automation | refers to automated machines | are generally lower | for automation technology. |

| For each new product | one of the most important | in which the equipment configuration allows | of programmable automation |

| Production rates | are programmed | is a good example | fixed sequence of processing operations. |

| A numerical-control | in programmable automation | must be | only certain processing operations. |

| Programmable automation | of the equipment in flexible automation | to reprogram and change over | than in fixed automation |

| The reprogramming | the production equipment | is done at a computer terminal | the production equipment for each series of new product |

Упражнение 8 Просмотрите текст и выберите ключевые словосочетания и выражения

Упражнение 9 Ответьте на вопросы:

What is the most important application of automation?

What are the types of automation used in manufacturing?

What is fixed automation?

What are the limitations of hard automation?

What is the best example of programmable automation?

What are the limitations of programmable automation?

What are the advantages of flexible automation?

Is it possible to produce different products one after another using automation technology?

Тест

“Types of automation”

Инструкция: Вставьте пропущенные слова, пользуясь таблицей, сделайте перевод

1. Manufacturing is one of the most important … … for automation technology.

2. The machines in fixed automation are programmed … … … to make only certain processing operations.

3. They are not easily … … from one product style to another.

4. This form of automation needs high initial … and high productions … .

5. Examples of fixed automation are machining transfer lines in the … industry, automatic … machines and certain chemical processes.

6. In programmable automation for each new product … … … must be reprogrammed and changed over.

7. This reprogramming and changeover take a period of … … .

8 Production rates in programmable automation are generally lower than … … … .

9. A numerical-control machine-tool is a … … of programmable automation.

10. The program is coded … … … for each different product style and the machine-tool is controlled by the computer program.

11. Programmable automation requires … to reprogram and change over the production equipment for each series of … .

12. The reprogramming of the equipment in flexible automation is done at a … … without using the production equipment itself.

| investments | automobile |

| the production equipment | assembly |

| in fixed automation | application areas |

| in computer memory | good example |

| by their design | rates |

| time | non-productive time |

| new product | computer terminal |

| - | changed over |

Упражнения для студентов, обучающихся по профессии

«Ремонтник горного оборудования»

Metals

Metals are materials most widely used in industry because of their properties.

The study of the production and properties of metals is known as metallurgy.

The separation between the atoms in metals is small, so most metals are dense.

The atoms are arranged regularly and can slide over each other.

That is why metals are malleable (can be deformed and bent without fracture) and ductile (can be drawn into wire).

Metals vary in their properties.

For example, lead is soft and can be bent by hand, while iron can only be worked by hammering at red heat.

The regular arrangement of atoms in metals gives them a crystalline structure.

Irregular crystals are called grains.

The properties of the metals depend on the size, shape and composition of these grains.

In general, a metal with small grains will be harder and stronger than one with coarse grains.

Heat treatment such as quenching, tempering, or annealing controls the nature of the grains and their size in the metal.

Small amount of other metals ( less than 1 per cent) are often added to a pure metal.

This is called alloying and it changes the grain structure and properties of metals.

All metals can be formed by drawing, rolling, hammering and extrusion, but some require hot-working.

Metals are subjects to metal fatigue and to creep (the slow increase in length under stress) causing deformation and failure.

Both effects are taken into account by engineers when designing , for example, airplanes, gas-turbines, and pressure vessels for high-temperature chemical processes.

Metals can be worked using machine-tools such as lathe, milling machine, shaper and grinder.

The ways of working a metal depend on its properties.

Many metals can be melted and cast in molds, but special conditions are required for metals that react with air.

Упражнение 1 Просмотрите текст и выберите ключевые словосочетания и выражения

Упражнение 2

Составьте словосочетания

| widely | over each other |

| between | grains |

| to slide | structure |

| regular | vessels |

| crystalline | lead |

| coarse | of the metals |

| heat | used |

| soft | by hand |

| small | fatigue |

| dense | treatment |

| bent | conditions |

| irregular | the atoms |

| properties | crystals |

| to add to | metals |

| metal | increase |

| pressure | arrangement |

| milling | stress |

| special | a pure metal |

| slow | amount |

| under | machine |

Упражнение 3

Составьте предложения из данных слов:

are / regularly /arranged/ The atoms/ and can slide over each other.

often /Small amount /( less than 1 per cent) added to/ of other metals /a pure /are/ metal.

vary /Metals/ in /properties /their.

on the size /The properties /of the metals/ depend, and composition /shape of these grains.

The study /is known/ of the production/ and as metallurgy./properties of metals

Упражнение 4

Определите соответствие между терминами и их определениями

| Metals are | can be deformed and bent without fracture

|

| Metallurgy is | can be bent by hand

|

| Malleable metals | the study of the production and properties of metals

|

| Ductile metals | can only be worked by hammering at red heat.

|

| Lead | materials most widely used in industry because of their properties. |

| Iron | the size, shape and composition of these grains

|

| The properties of the metals depend on | can be drawn into wire

|

| Types of heat treatment are | small amount of other metals is added to a pure metal |

| Alloying | lathe, milling machine, shaper and grinder.

|

| Machine-tools are

| quenching, tempering, or annealing |

| The main processes of metal forming are | drawing, rolling, hammering and extrusion

|

Упражнение 5 Ответьте на вопросы:

What are metals?

What do we call metallurgy?

Why are most metals dense?

What is malleability?

What are grains?

What is alloying?

What is crystalline structure?

What do the properties of metals depend on?

What are the main processes of metal forming?

What is creeping?

Упражнение 6

Определите типы обработки металла и найдите их определения в тексте:

1

2

3

4

5

Упражнение 7

Вставьте пропущенные слова, пользуясь таблицей, сделайте перевод

Metals are materials most … used in industry because of their…..

The … of the production and properties of …. is known as metallurgy.

The … between the atoms in metals is small, so most metals are… .

Metals … in their properties.

The regular arrangement of atoms in metals gives them a … structure.

… crystals are called grains.

The properties of the metals … on the size, … and composition of these grains.

In general, a metal with small grains will be … and stronger than one with coarse grains.

Heat … such as quenching, tempering, or annealing controls the nature of the grains and their size in the metal.

Small …. of other metals are often added to a … metal.

All metals can be formed by drawing, rolling, … and extrusion, but some require hot-… .

Metals are subjects to metal … and to creep causing deformation and failure.

Metals can be worked using … such as lathe, milling machine, shaper and … .

The … of working a metal depend on its properties.

| metals | irregular | vary | widely | amount | study |

| harder | properties | crystalline | treatment | separation | fatigue |

| working | machine-tools | shape | dense | hammering | depend |

|

| ways |

| grinder | pure |

|

Прочитайте текст

Steel

1. The most important metal in industry is iron and its alloy — steel.

2. Steel is an alloy of iron and carbon.

3. It is strong and stiff, but corrodes easily through rusting, although stainless and other special steels resist corrosion.

4. The amount of carbon in a steel influences its properties considerably.

5. Steels of low carbon content (mild steels) are quite ductile and are used in the manufacture of sheet iron, wire, and pipes.

6. Medium-carbon steels containing from 0.2 to 0.4 per cent carbon are tougher and stronger and are used as structural steels.

7. Both mild and medium-carbon steels are suitable for forging and welding.

8. High-carbon steels contain from 0.4 to 1.5 per cent carbon, are hard and brittle and are used in cutting tools, surgical instruments, razor blades and springs.

9. Tool steel, also called silver steel, contains about 1 per cent carbon and is strengthened and toughened by quenching and tempering.

10. The inclusion of other elements affects the properties of the steel.

11. Manganese gives extra strength and toughness.

12. Steel containing 4 per cent silicon is used for transformer cores or electromagnets because it has large grains acting like small magnets.

13. The addition of chromium gives extra strength and corrosion resistance, so we can get rust-proof steels.

14. Heating in the presence of carbon or nitrogen-rich materials is used to form a hard surface on steel (case-hardening).

15. High-speed steels, which are extremely important in machine-tools, contain chromium and tungsten plus smaller amounts of vanadium, molybdenum and other metals.

Упражнение 8

Составьте словосочетания:

| influences | instruments |

| corrodes | surface |

| suitable | its properties |

| cutting | metal in industry |

| surgical | chromium |

| razor | blades |

| strengthened and toughened by | through rusting |

| transformer | materials |

| corrosion | of sheet iron, wire, and pipes. |

| nitrogen-rich | tools |

| hard | of other elements |

| high-speed | for forging |

| the most important | quenching and tempering. |

| the manufacture | steels |

| addition of | cores |

| inclusion | resistance |

Упражнение 9

Прочитайте текст, переводя слова

1.The most important metal in industry is iron and its alloy - сталь.

2.Steel is an сплав of iron and углерод.

3.The количество of carbon in a steel influences its properties значительно.

4.Steels of низкое carbon content (mild steels) are quite эластичные.

5.Medium-carbon steels содержащие from 0.2 to 0.4 per cent carbon are крепче and stronger and are used as конструкционные steels.

6.Both mild and medium-carbon steels are подходящи for forging and сварка.

7.The включение of other elements affects the свойства of the steel.

8.The добавление of chromium gives extra strength and коррозия resistance, so we can получить rust-proof steels.

9.Нагревание in the presence of carbon or nitrogen-rich materials is используется to form a hard surface on steel (упрочнение).

10.Быстрорежущие steels, which are extremely important in станки, contain chromium and вольфрам plus smaller amounts of vanadium, molybdenum and other metals.

Упражнение 10

Вставьте пропущенные слова, пользуясь таблицей, сделайте перевод

1. The most … metal in industry is iron and its …— steel.

2. Steel is an alloy of iron and….

3. The …of carbon in steel influences its … considerably.

4. Steels of low carbon content (…steels) are quite … and are … in the manufacture of sheet iron, wire, and pipes.

5. Medium-carbon steels … from 0.2 to 0.4 per cent carbon are used as structural steels.

6. … mild and medium-carbon steels are … for forging and welding.

7. High-carbon steels are hard and … and are used in … tools, surgical instruments, razor … and springs.

8. Tool … , also called silver steel, is strengthened and … by quenching and … .

9. The … of other elements … the properties of the steel.

10. The addition of chromium …extra strength and resistance, so we can … rust-proof steels.

11. High-… steels are extremely important in … .

| carbon | mild | properties |

| Both | important | cutting |

| ductile | steel | alloy |

| blades | amount | containing |

| brittle | tempering | used |

| toughened | suitable | affects |

| inclusion | corrosion | machine-tools |

| get | gives | speed |

Прочитайте текст

METAL-CUTTING MACHINES LATHES

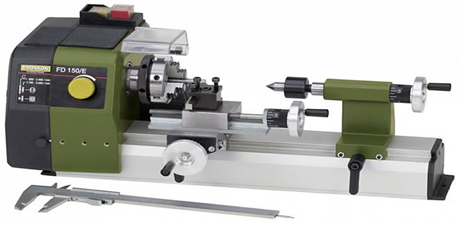

1. A lathe is known to be essentially a machine tool for producing and finishing surfaces of work pieces.

2. The machine is designed to hold and revolve work around an axis of rotation so that it may be subjected to the action of a cutting tool moving in a horizontal plane through the axis of the work.

3. When the cutting tool moves in a longitudinal direction or parallel to the axis, the operation is known as "turning"; when it moves in a transverse direction, it is known as "facing".

4. In addition to turning and boring, which the machine is primarily designed for, many other operations, such as drilling, threading, tapping, and, by employing special adapters grinding and milling, may be performed on a lathe.

5. Lathes used in shop practice are known to be of different designs and sizes.

6. These lathes fall into various types, either according to their characteristic constructional features, or according to the work for which they are designed.

7. The size of a lathe is determined by the diameter and length of work that may be swung between centers.

8. Lathes of comparatively small size, which may be mounted on a bench, are termed bench lathes, and are intended for small work of considerable accuracy; lathes provided with tools held in a revolvable turret are called "turret lathes": lathes in which work pieces to be treated are held in a chuck are known as "chucking lathes"; lathes in which most of operations are performed automatically are named "automatic lathes".

9. Besides there are also many special-purpose lathes such as crankshaft lathes and wheel lathes for turning crankshafts or engine driving wheels respectively; screw-cutting lathes for threading screws, etc.

10. The engine lathe used for metal-turning operations is fitted with a power-actuated carriage and cross-slide for clamping and holding the cutting tool.

11. In engine lathes the cutting tools are generally guided by the machine tool itself, in other words, they are operated mechanically, while in some lathes the cutting tools are guided by hand.

12. The engine lathe consists essentially of the following basic parts: the bed, the headstock, the tailstock, the feed mechanism, and the carriage.

Определите типы станков, найдите описание одного из них в тексте

1

2

3

4

Упражнения для студентов, обучающихся по профессии «Сварщик»

Прочитайте текст

WELDING

Welding is a process when metal parts are joined together by the application of heat, pressure, or a combination of both.

The processes of welding can be divided into two main groups: a) pressure welding, when the weld is achieved by pressure; b) heat welding, when the weld is achieved by heat.

Heat welding is the most common welding process used today.

Nowadays welding is used instead of bolting and riveting in the construction of many types of structures, including bridges, buildings and ships.

It is also a basic process in the manufacture of machinery and in the motor and aircraft industries.

It is necessary almost in all productions where metals are used.

The welding process depends greatly on the properties of the metals, the purpose of their application and the available equipment.

Welding processes are classified according to the sources of heat and pressure used.

Welding processes widely employed today include gas welding, arc welding and resistance welding.

Other joining processes are laser welding, electron-beam welding.

Упражнение 2

Составьте словосочетания

| Gas | metal |

| metal | weld |

| filler | equipment |

| welding | of bolting |

| portable | process |

| fusible | welding |

| defective | of heat |

| instead | industry |

| basic | edges |

| application | material |

| aircraft | rod |

Упражнение 3

Изучите текст, выпишите ключевые слова и выражения

Упражнение 4

Составьте предложения

| 1 2 3 4 5 6 | Welding is | is portable | in all productions where metals are used. |

| The welding process

| is a non-pressure process | the form of wire or rod and is called the welding rod | |

| Welding

| has | and does not require an electric power source. | |

| Gas welding

| a process | on the properties of the metals, the purpose of their application and the available equipment. | |

| Filler metal | and the welding rod | are coated with flux | |

| Gas welding using equipment | depends greatly | when metal parts are joined | |

| 7 8 | The surfaces to be welded | is the most common | welding process used today. |

| Heat welding

| is necessary almost | using heat from a gas flame. |

Упражнение 5

Назовите виды сварки на русском и английском языках.

Упражнение 7

Переведите на английский язык:

край

наполнитель

поверхность

покрытый

флюс

плавкий

заслонять, защищать

проволока

прут, стержень

плавить(ся)

соединение, стык

преимущество

требовать нуждаться

одновременно

касание

пламя

Упражнение 6

Вставьте пропущенные слова, пользуясь таблицей, сделайте перевод

Welding is a process when … … are joined together by … of heat, pressure, or a combination of both.

Nowadays welding is … instead of … and riveting in the … of many types of structures, … bridges, buildings and ships.

It is also a … process in the manufacture of machinery and in the motor and … industries.

It is … almost in all productions where … are used.

The welding process depends greatly on the … of the metals, the purpose of their application and the … equipment.

Welding processes widely employed today include gas welding, … and resistance welding.

… is a non-pressure process using heat from a gas … .

Gas welding has the … of using equipment that is … and does not … an electric power source.

The surfaces to be welded and the … … are coated with flux, a fusible material that … the material from air, which would result in a defective weld.

| properties | bolting |

| used | basic |

| gas welding | shields |

| including | aircraft |

| the application | construction |

| advantage | metals |

| necessary | arc welding |

| available | flame |

| portable | require |

| metal parts | welding rod |

Упражнения для студентов, обучающихся по профессии «Электромонтёр по ремонту и обслуживанию электрооборудования»

Electricity

Electricity is something that we use every day, and sometimes don’t realize how much we use it, or depend on it.

There are two famous scientists who worked with electricity a lot – Thomas Edison, and Nicholas Tesla.

Both of them made very big discoveries in electricity and science in general.

We get electricity from power plants that send energy to other electricity centers that give it to our homes.

5. It is difficult to imagine life without electricity now.

6. It is something that is necessary for everyday life for most people.

7. We need it to work and to relax, to watch TV, to cook and so on.

8. In the past people didn’t have electricity and I can’t even imagine how they lived.

9. They use candles and oil lamps, stoves and so on.

10. Nowadays it is even popular to go on special vacations to places that don’t have electricity.

11. These places try to give people the experience of living like it was in the past.

12. It also gives you the chance to find a connection with nature and have a better understanding of the world that we live in.

13.For me, electricity is a necessity, I use it to play video games, watch television, and read using a lamp.

14. However, I really enjoy going out to the countryside where we use fire for keeping warm and cook food.

15.Thinking about all these makes us understand that we shouldn’t take everything for granted but be happy about what we have.

Упражнение 1

Прочитайте текст, сделайте пересказ.

Упражнение 2

Составьте словосочетания:

| electric | resistance |

| atmospheric | system |

| sea | current |

| electrical | moisture |

| cooling | temperature |

| water | pressure |

| fire | distance |

| set | force |

| amount of | level |

| certain | warning |

| acceleration | fluid |

| flow of | vapour |

Упражнение 3

Найдите соответствия между терминами и их определениями

| voltmeter | measures or controls temperature – produces a voltage which varies proportionally as the temperature difference between two points varies |

| ammeter | detects and measures electrical resistance |

| ohmmeter | regulates temperature – switches a heating or cooling system on or off at a set temperature |

| thermostat | measures or controls temperature – produces a resistance which varies proportionally as the temperature varies |

| thermocouple | detects and measures electric current |

| thermistor | a general term for devices that detect and measure light |

| photo sensor | measures the distance between itself and nearby objects |

| proximity sensor | detects and measures voltage |

| piezoelectric sensor | measures atmospheric pressure |

| flow meter | measures movement and strain – produces an electric current when stressed mechanically |

| barometer | measures altitude, usually as a height above sea level |

| hydrometer | measures acceleration and deceleration forces |

| altimeter | detects sound |

| smoke detector | measures the rate of flow of fluid |

| accelerometer | detects movements – usually of people – that are a certain distance away |

| motion detector | measures the amount of moisture(water vapor) in the air |

| microphone | detects smoke, usually to provide a fire warning |

Получите свидетельство

Получите свидетельство Вход

Вход

Комплект упражнений для профессий СПО (2.58 MB)

Комплект упражнений для профессий СПО (2.58 MB)

0

0 1928

1928 63

63 Нравится

0

Нравится

0